Onmuse Office Furniture Co.,Ltd

Furniture Legs Manufacturers and Suppliers in the China

-

Most of this model is made to order,but the material such as L-die casting, T-die casting and raw material of the steel tubing we have stock.

-

The metal table legs was made of T-6063 aluminium and produced by 800T die casting machine.

-

With 2 type of treatment one is chrome and powder coating finish.

-

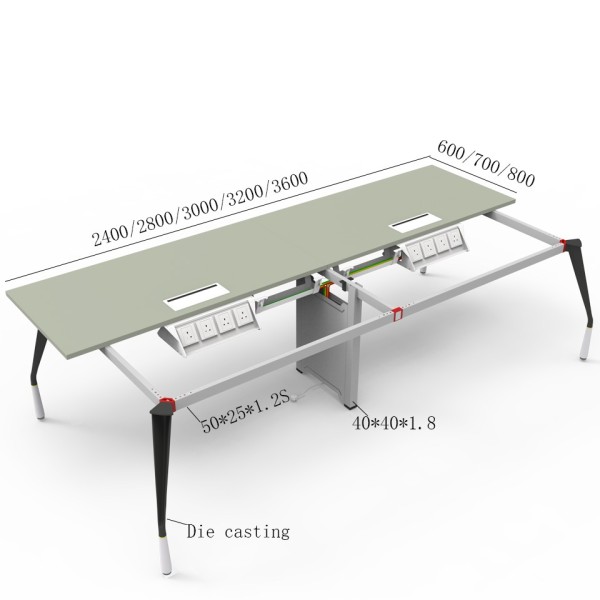

The top frame was loop shape,this type of structure is more stable compare than others

Attrs

- Metal table base with 50x25x1.2 steel beams

- With adjustable glide with 0mm to 20mm adjustable range

- 25MM worktop with E0 core material,2mm pvc edge banding

- Size can be customized

- Height=750H

- Chrome or Powder coating finish

- 10 years warranty

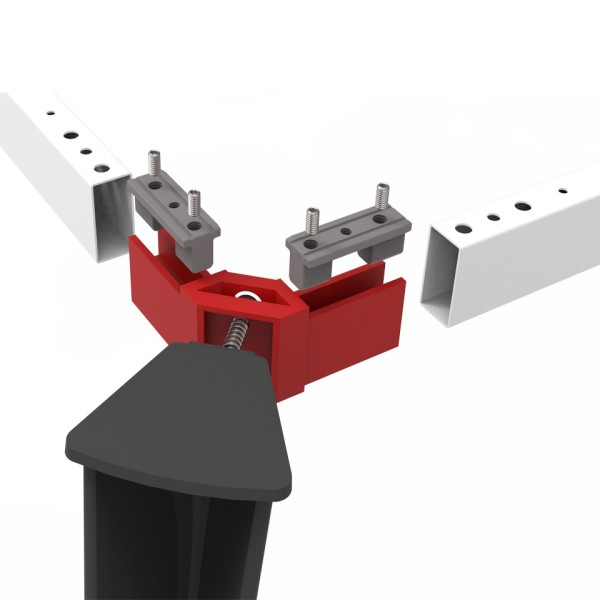

Very spcial fastener design with registered patent in China

-

This L shaped fastener have patent design in China,the fastener lenght 60mm long.

-

The L-shaped connector of this products weights 325G, each with 2 sliders and tight with M8x20 stainless steel screws. When using,just insert the gray and red parts in the picture into the 50x25 steel pipe. tighten the scews. and you can very tight fixe the L-shaped connecto and beam together, Then use M10x40 screw to fix the L shaped connector and the die casting leg together, The entire production and installation process is very simple and quick

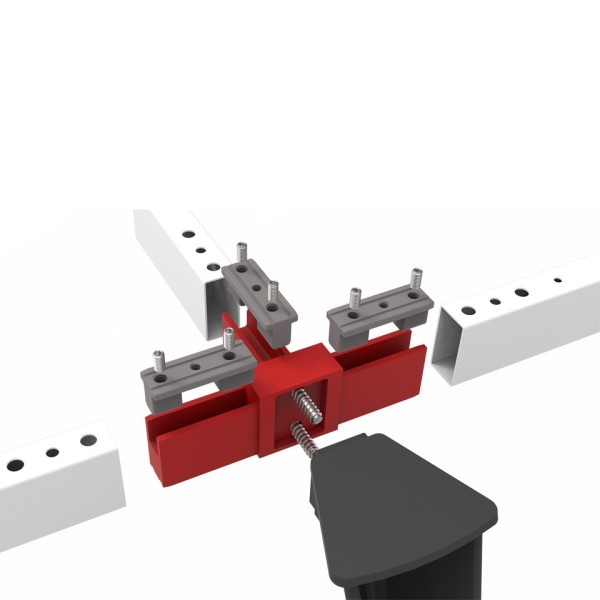

T-shape table leg fastener

-

The design principle of the T-shaped fastener is same that of the L-shaped one.They both use same sliders and screws,which can reduce production costs,The T-shaped connector can not only be directly connected to the die casting leg,but also connected to the cable riser,realing the multi-purpose use of the accessories.

-

This mult-prupose design conect can not only reduce production and inventory costs,but also allows for simple and quick installation without the need for a lot of time.

The 4 person workstaion structure

-

This type of KD structure,the production effeciency very high, except this we also have following advantage.

-

Our machiner and equipment are very advanced,including 4-axis laer cuting equipment and CNC drilling machines, The high precision of these devices ensures that the overall size tolerence of the proudcts during production does not eceeed 1mm and the hole position tolerance does not execeed 0.1mm.

-

High-precision equipment allows us to complete product production quickly and accurately, reducing product waste and rework due to size errors, Thereby saving production costs.

120 Degree Workstation structure.

-

The 120-degree workstation is an innovative furniture layout design,Breaking away from traditional furniture layouts and offering users a fresh visuall and usage experience. This furniture layout method changes the monotonous form of furniture to a certain exten.making the product more design-oriented and mordern,giving people a fresh feeling.

-

However,this design method does have certain drawbacks, Firstly.the design of the 120-degree workstation usually takes up more space,which may be inconvenient for users with limited space.Secondly,the space utilization rate is relatively low.If customer want to make full use of space,this layout may not meet their needs.

We provide customized services without MOQ to limit

-

With the changes in office environment,the size of offices is becoming smaller.The ear when a single projects order consisted of thousands or tens of thousands of workstation has become a thing of the past.Currently,the demand for offices usually ranges from 50 to 300 workstations,especially for some managers or directors office,they are paying more and more attention to personalization and the demand for customized products is increasing,this is trend.

-

We now offer customized services to meet this changing demand.we can customize the furntiure based on customer requirement.such as material selection,color matching,Moreover,we do not have MOQ to limit

We provide 10 years warranty

-This type of leg LF-87 Seperate 2 parts, and there is a gold ring between the parts.

- We also have similar design as LF-87,the Model no HAWK leg also seperate 2 parts.

Black Metal Table Legs

The table top E0 core material

All the table top,the core material are all E0 rating,

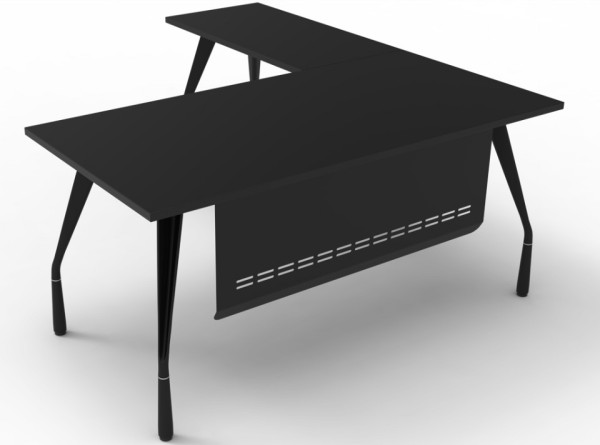

Black Executive Desk

We are using Azku Nobel powder coating(Without VOC)

-

We are using Azku Nobel powder coating for all our metal table legs,so the powder coating we are using without volatile organic compounds(VOC) and solvents.

-

Make sure the office health.

4 person workstation with 16mm framless desk screen

For wooden top we have 20 color options

-

Our wooden products come in a wide variety of colors to suit your personal style and home decor. We offer 20 unique color options, ranging from traditional wood tones like oak, mahogany, and walnut, to more contemporary choices such as gray, white, and black. Each color is carefully selected and applied to bring out the natural beauty of the wood grain, adding a touch of elegance and sophistication to your space.

-

Whether you prefer a warm, rustic look or a sleek, modern aesthetic, you're sure to find the perfect color option in our selection

Table legs we provide 13 color options

-

For powder coaing color swatch, we will replace it every 2 years, our marketing Dept will select the currently popular colors based on the market research.

-

In addition, some colors that are used by customers for long time, we will retain

Categories

FAQs

1. How to stabilize a shaky table legs metal?

Customers really like the metal table legs produced by our factory because they are very stable. Here are some of our experiences in producing metal legs for your reference and discussion.

-

One very important factor is the choice of material. For steel metal legs, we use cold-rolled steel tubes or plates. The most important thing is that the thickness of the tube or plate must meet the requirements. Our minimum thickness of the tube not less than 1.8mm. Most factories on the market use the thickness of 1.4mm steel tube. Furniture produced with this thickness basically does not meet the stability requirements. Therefore, under the same conditions, the cost of our factory's products is higher than that of other factories, and the price is also relatively higher than other factories. However, our products are well received by customers due to their good stability.

-

The structural design of the product is another important aspect of product stability. The crossbeams of our products basically adopt a loop shape structure. This structure makes the force on each part very even, thereby increasing the stability of the product.

-

This the installation skills. using a big size washers, this is a easy and quick way to solve the the problems of table leg shaking. Use a washer that is 1.5-2 times larger than the screw head, and place all the screws on the washer. In this way, when you tighten the screws, you will find that your table is no longer shaky.

-

Adding a triangular bracket at the connection of the legs can enhance stability. Once the triangular bracket is installed, you will find that your table is very stable. However, this method can compromise the aesthetics of the table, making it more suitable for reinforcing old furniture. For new furniture, we may need to find more ingenious ways to enhance stability without affecting aesthetics. For instance, we can consider stability issues in the design stage, opt for a more stable structural design, or use higher quality materials during production. Regardless, our goal should always be to provide consumers with stable, durable, and aesthetically pleasing products