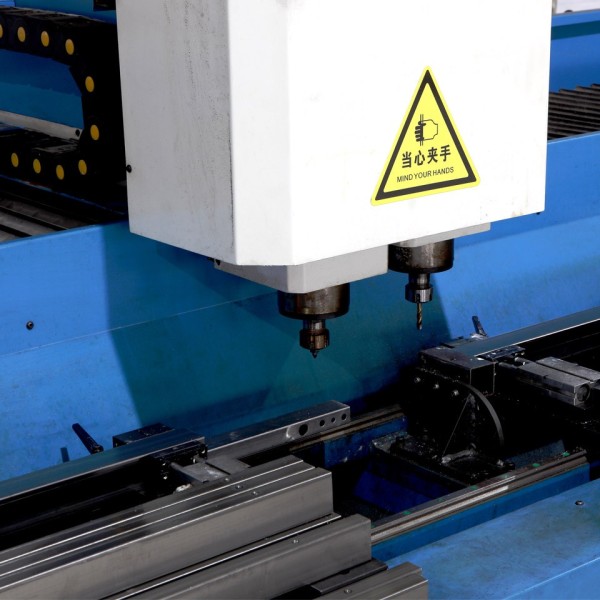

This Is Drilling And Tapping Machine

This is a highly efficient drilling and tapping machine, capable of drilling 30 holes per minute. It first drills a hot melt hole, then proceeds to tap. This hole position matches perfectly with the screw, which can enhance the strength of steel pipes or steel plates.

Automatic Drilling Machine

-

This is a CNC drilling machine equipped with dual drill heads, one is a hot melt drill head, and the other is a tapping drill head. The entire drilling machine is 3 meters long and 1.2 meters wide, with the maximum processing length also being 3 meters. It can drill 25-30 holes per minute and can process steel pipes of various shapes. The size of the holes can also be customized according to the customer's needs.

-

This CNC drilling machine is simple to operate, and it is highly efficient, precise, and flexible. The high drilling speed greatly improves production efficiency, and the precise hole position and diameter ensure the quality of the product.

This Is Part Of Drilling Workshop

The drilling workshop combine with punching workshop, in this workshop we have 8pcs CNC drilling machine

We can process around 400-700 workstations per day.

-

The punching machine are capable of processing a variety of different materials. such as steel tubing and steel plates.Whther it's steel modesty panel of steel panel for panel based workstations,or puching the steel tube.all can be processed by the punching machine

-

The precison and efficiency of the machines allow us to completea large number of processing tasks in a short period of time.

The punching machine workshop

-

We have different of puchining machines,from 50T to 1600T puching machines we all have it.

-

Total we have 30pcs puching machines,it can meet all sheet metal requirement.

Steel Plate Laser Cutting Machine

-

This laser cutting machine performs excellently,the power is 3KW,it can easily cut steel plate with a thickness of up to 30mm,its cutting speed can reach 15m per minute,and it can cut products of various shape.

-

All we need to do is input the CAD drawings into the machine, and it can cut precisely according to the design of the drawings.The efficient and accurate processing method greatly improves the production efficiency and saves a lot of labor costs

Steel Tube Laser Cutting Machine

This steel tube laser cutting machine is same performance as our steel plate laser cutting machine,also high efficiency and more convenience and save labor cost

Efficient Sheet Metal Workshop

Our sheet metal workshop can process all kinds of prodcts,such as metal trunking/steel cabler riser/steel modesty panel/plant box/dining table legs

Metal Table Leg Welding

All metal table legs need to be welded after being cut. We usually use two methods: carbon dioxide welding and argon arc welding. For small orders, we typically have skilled workers perform the welding. The quality of the welding process directly affects the quality of the product, so the requirements for workers' welding skills are quite high. Our workshop has over 18 employees with many years of welding experience. They have all undergone strict training and assessments, are skilled and experienced, and can ensure the quality of the welding work

Grinding workshop

Metal Leg Grinding

- All metal table legs need to be ground after welding. The grinding process must be carried out by skilled workers to ensure that the shape of the steel pipe does not change during the grinding, and the lines must remain smooth.

-The intensity of the grinding must be moderate, neither too light to result in incomplete grinding, nor too heavy to damage the surface of the steel pipe. Our factory has 25 such skilled workers. They have all undergone rigorous training and have rich grinding experience to ensure that the grinding work of each product achieves the best effect

Polishing The Metal Table Legs

After welding, there are welding scars on the steel table legs, they need to be polished. During this process, we use a 500# polishing wheel to polish the welded area, making two adjacent steel pipes polished into a whole. This process also requires skilled employee. They not only need to have superb skills, but also rich experience to ensure that the polishing achieves the best effect.

Automatic Welding Robot

-

Our factory has 4 automatic welding robots. Once the components to be welded are placed on the workbench, the welding robot can automatically identify the components and perform precise welding. The technical level of these robots is equivalent to a technician with 10 years of welding experience, and they are very simple to operate, requiring only one person to complete all operations.

-

These automatic welding robots have lightened the workload of our workers. The work efficiency of one welding robot is equivalent to the total workload of four technical personnel.