Onmuse Office Furniture Co.,Ltd

Folding&Training table-wholesale folding tables and chairs

-

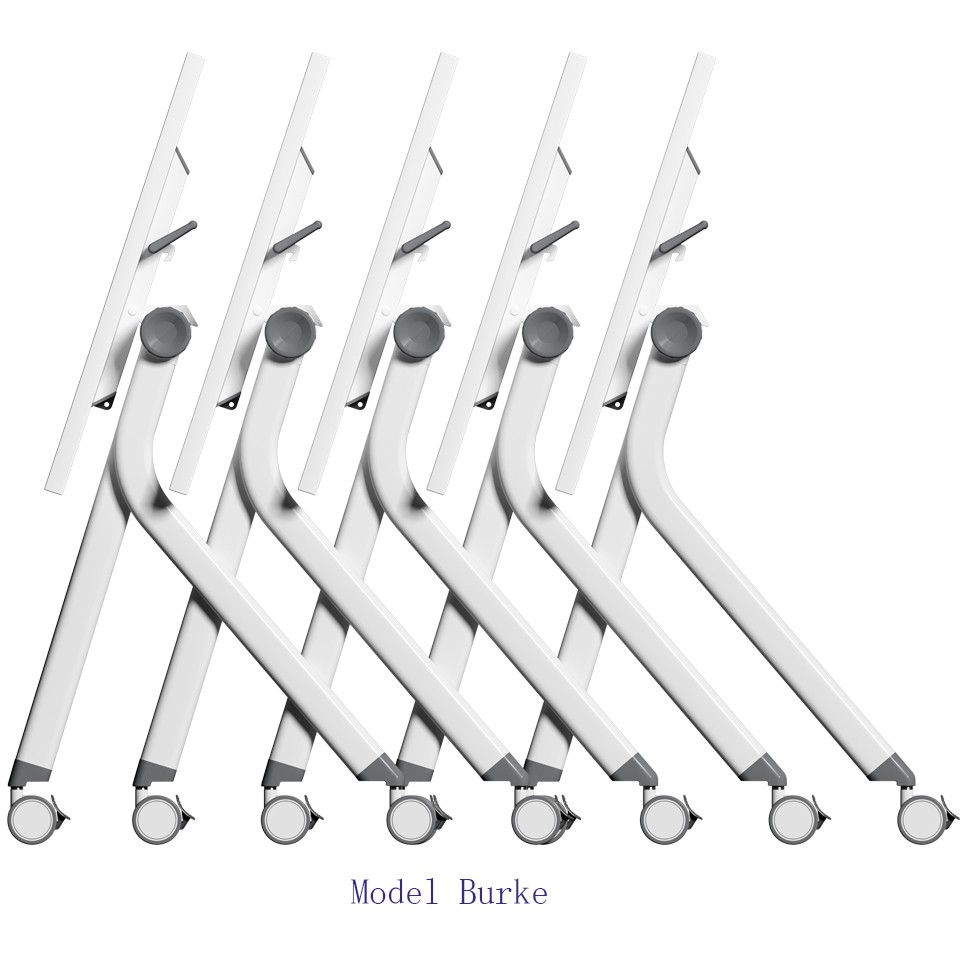

This is very sturdy office training desk,the base of which is produced by an 800T die casting machine, and the top has an integrated weld frame,the loading compactiy up to 250KG.

-

The installation process is simple and quick, and the entire process can be completed in just 3-4 minutes, The packaging of the proudct is that each set of products is individually packaged.

-

The paint users famous brand Akzo Nobel.

Attrs

- Durable, 1" thick laminate top with 2 cable grommets. 29 1/2" height.

- Two flip handle. Quickly flip top from either end of table.

- Die casting footbase and steel post

- 3" locking PU swivel casters.

- 25MM MFC table top,top range 1000Lmm to 2000Lmm

- Loading compacity up to 250KG

Quick production lead time and prompt delivery

-

In order to quickly occup market share,we must meet users' demands for urgent orders. Some customers require very short delivery times

-

Which requires our folding training tables design to be standardized, and there must be a certain amount of stock for raw materials and accessories.

-

We have a certain amount of stock for each component of our training desk. when a customer places an order.we can provide the product in the shorest possible time.

-

Our normal delivery time is for the quantity of a 40HQ of the products.with a delivery period of 7-12 days. and special orders can be completed within a week

We dont have MOQ limit

-

We understand that each customer's needs are different and the quantity they purchase may vary. we adhere to the philosophy of growing together with our customers.

-

Even if it's just purchase of a single folding training table,we will serve you with 100% enthusiasm and professionalism.

All the powder from famous supplier Akzo Nobel

- In our market research,we found that about 30% of customer complaints focus on the surface treatment of the folding legs for table.

-These complaints mainly revole around poor adhesion of the powder coating. and the film surace not being delicate.giving a feeling of low quality.

- To solve this problem,we have chosen the world renowned brand Azko Nobel powder coating

We provide customize service

-

For some projects customers need to customized the products.inculding the siz,color and sometimes even shape.

-

we can customize according to the user's needs. we provide personalized products services to our customers.

1 set training desks in one seperate cardboard box.

-

Our standard package is one set products in one box.in this case it is easy for customers to sort the goods when they received the containers

-

The packing instruction only show how we packed the goods.

-

The real package each component is protected and there are other packing material seperated between the component.

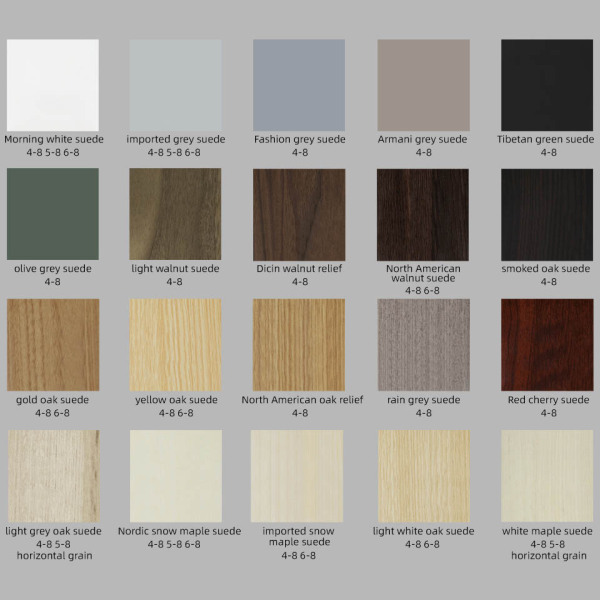

For wooden top we have 20 pieces color options

-

Our wooden tabletop color cards offers 20 different colors for selection.all of which are carefully picked from the currently popular international color cards.

-

The color swatch inculdes both wood grain and solid colors. providing a wide range of choices for users to meet their different color needs.

For training desk legs we have 13 color options

Our training table leg color cards offers 13 pieces different colors for selection.all of which are carefully picked from the currently popular international color cards. and these color match the international RAL color swatch.